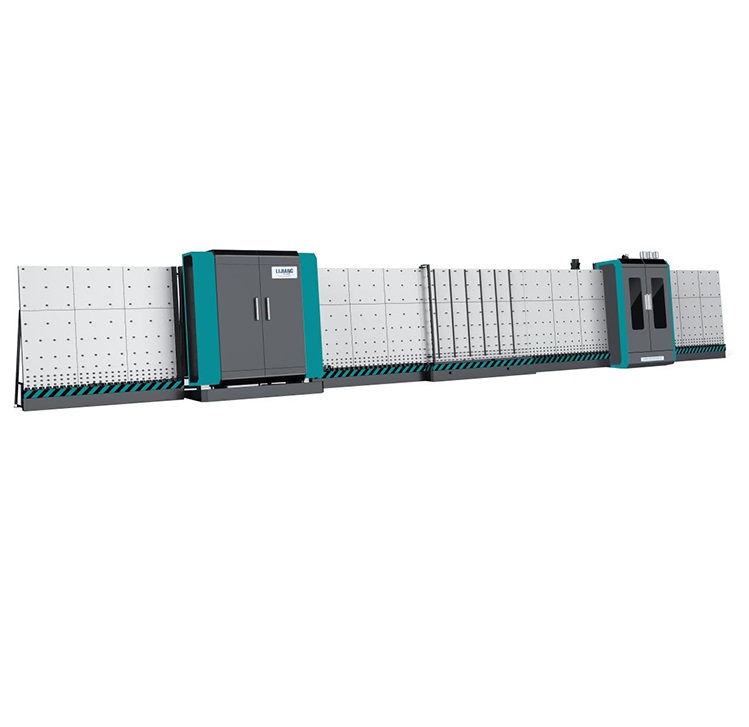

The whole LJBZ2535 Insulating Glass Production Line has 7 sections: 01 transfer section;

02 washing machine;

03 discharge section;

04 inspection and installation section;

05 transfer section;

06 pressing and filling section;

07 discharge section.Optional functions: •Step glass with optional edges

•Shaped glass

•Filling argon gas automatically

•Air-floating technology to transfer glass

•PLC control system, touch screen interface

•Using Siemens servo motors

•Applicable to produce double glass, triple glass

To prevent the glass from being contaminated by wheels and leaving traces to improve the IG production’s high quality.

LJBZ2535G Automatic Vertical Insulating Glass Inflatable Inside and Outside Plate Production Line

1. Automatically drill holes for filling argon gas (Optional)

2. Spacer printing code function (Optional)

3. Printing label sticker function (Optional)

4. Bending shape frame. Use a circle wheel device to bend a circle frame or frame with circle corners. Min R60, Max R150, spacer sizes: 6A – 16A).

Product Details

LJBZ2535G Automatic Vertical Insulating Glass Inflatable Inside and Outside Plate Production Line Adopt SIEMENS Control System

Product Description

LJBZ2535 Automatic Insulating Glass Production Line

The second part is the washing and drying section.

In this glass washing and drying section, there are three pairs of soft brushes and four pairs of water spray for washing and drying glass.

The air knife is float designed, which part always keeps the right and suitable distance between the glass and air knife in the press and design section. ( Entirely as same as the LISEC )The transfer wheel from this section: The front and back transfer wheel is all-direction moved, all actively transferred. Whether the glass size is big or small, it always guarantees the glass pass through smoothly. ( Entirely as same as the LISEC )The axle and bearing of brushes adopt all stainless steel, which could keep the machine can washing stabilized and used for a long time.

The whole drying machine uses a sound insulation design, which could reduce noise pollution effectively.

The 6th part: the pressing and gas filling section.

In this section, it could adopt online input of the suitable gas proportion value, all the data could show off on the touch screen, and during the gas filling processing, the touch screen can show off the whole gas filing process visually.

However, how to show off the percentage of the argon gas filling on the touch screen online, is the importance of technology in insulating glass production. Jinan Lijiang Glass, which is the first and the only manufactory, could master this technology very well from China.

There is no doubt that it could be very useful for customers, when argon gas is filling, it will show off the whole processing on the screen. When it reaches the customer setting data, It will alarm and stop immediately. So it not only can save the argon gas but also can save the processing time.

By the way, the bottom of gas filling is our special structure. (Entirely as same as the structure of LISEC) The whole press and gas filling section is divided into five parts (per 750mm), when the small size glass (less than 750mm) passes through the pressing and gas filling section, only one part could work.

When the difference size glass, which glass is more than 750mm but less than 1500mm, passes through the pressing and gas filling section, it will two parts work, no need for the whole press and gas filling section to work, to save more the argon gas.

Advantages & Features

Benefits & Advantages

Adopt SIEMENS control system, keep stable performance

PLC control system, touch screen interface

Automatically adjust the depth of glue with a digital display

Using servo to control system, modular function, superposition function

Applicable to produce stepped IG, triple IG, and shaped IG

Two pieces of IGU can be made and filled with argon gas at one time (Optional)

Min & Max glass sizes can be optional

European design concept, simple and smart operation;

the world-famous brand of core components, ensure stable operation and long service life;

It is designed for processing high-quality glass, such as reflective glass, Low-E glass, reflective glass, and tempered glass;

Large glass processing size, various models, and customization available;

Large production capacity, output 1,000pcs in working days;

It can be used for two-layer, three-layer, pad, and glass with irregular shapes;

Automatic air gas filling during the glass paper assembly process.

The coating inspection

To avoid the Low-E glass or Coated glass put inverse side and Leave wheel marks or scratch Low-E Coating, Jinan LIJIANG Glass uses coating inspection -metal film conductive. (other suppliers from China, usually use the photoelectric detection, and it's actually a little hard to recognize for higher transparent)

The pressing box uses the high-precision servo motor.

The servo motor could be accurately calculated the thickness of the Insulated glass and aluminum spacer. Compared with the traditional hydraulic stations. And also, it could guarantee the precise working pressure and protect the glass from damage, at the same time increasing the working speed.

It uses six soft (Low-E Glass) brushes with a 0.1mm diameter only.

It has 6 brushes which are all soft brushes and could wash and dry more different types and sizes of Low-E glass, flat glass,

tempered glass, and so on. It has a diameter of less than 0.1mm bristles, and never damages a glass, especially for Low-E glass washing.

The whole washing machine all uses #304 stainless steel materials

The whole washing and drying section adopts #304 stainless steel materials, including the plate and interior spare parts. The thickness plate can be up to 4mm and the interior plate can be 8mm. The equipment performance is better and the service life is much longer than other suppliers.

Air floating technology - Optional

The front and back transfer wheels are all moved, all actively transferred. It can guarantee the big and thick glass passes through smoothly. The equipment adopts the new air–floating technology that uses air to support glass and transfer glass. When glass is washed clearly from the washing machine, using air to transport the glass, it won't be contaminated. Ensure that the produced insulating glass is of the highest quality.

The first one is to use adjustable points to ensure that the platen will never deform.

The whole equipment adopts CNC technology into the pressing board. It was designed the adjustable points inside the pressing board to keep the backplate straight all the time. In China, except LIJIANG, no other suppliers could guarantee that the pressing board will remain vertical and straight all the time after being used for over 10 or 20 years.

Main Technical Parameter

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close