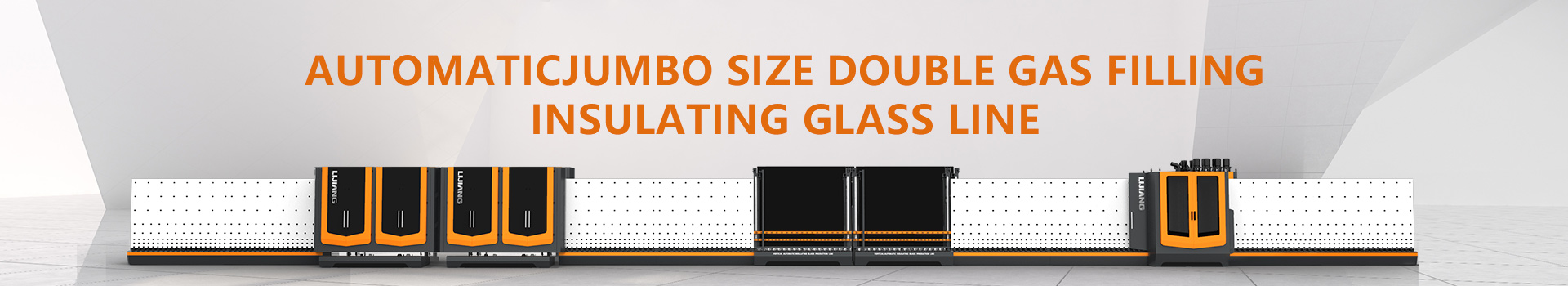

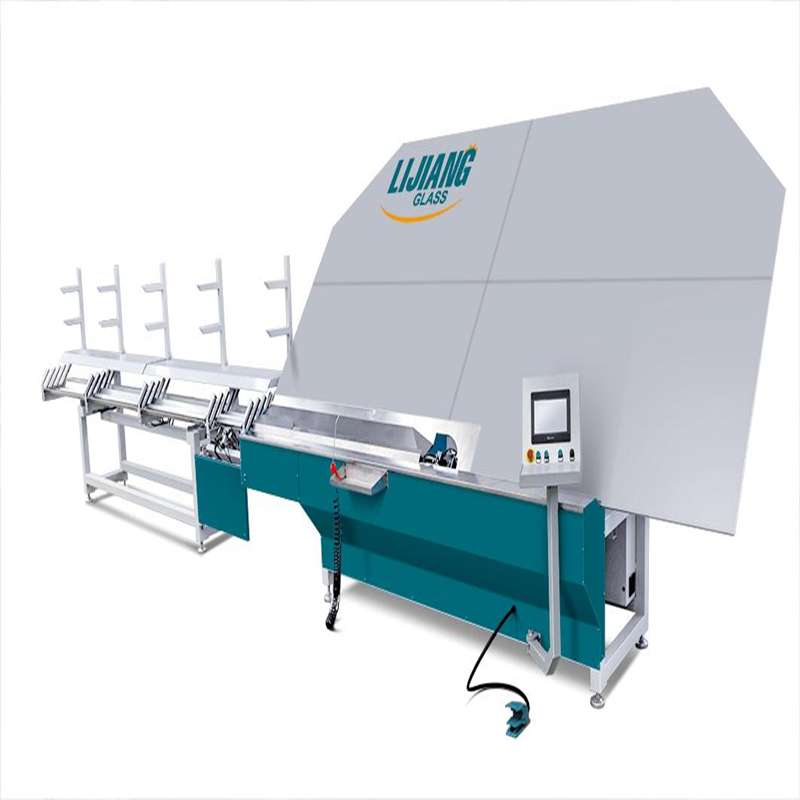

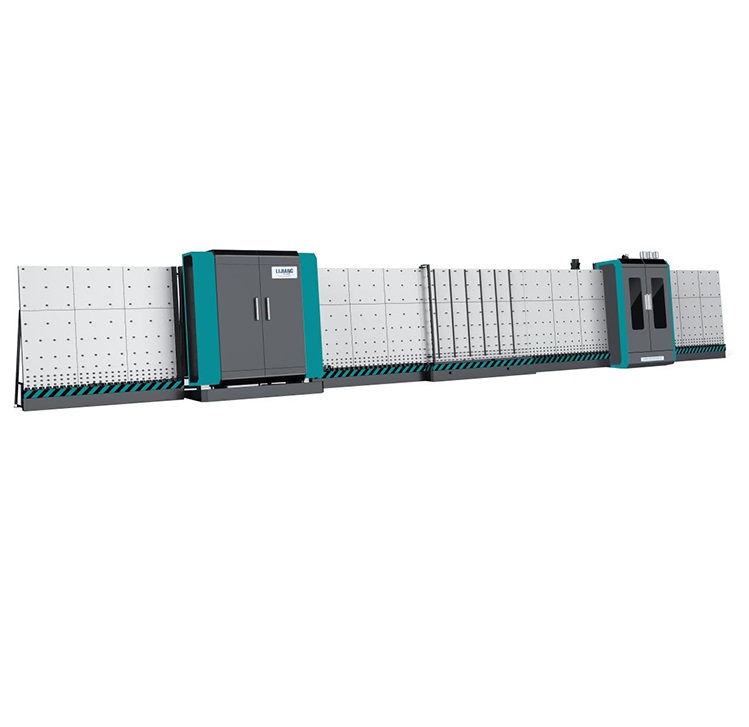

Insulating Glass Aluminum Spacer Foldable Special Shape Bending Machine

1. Automatically drill holes for filling argon gas (Optional)

2. Spacer printing code function (Optional)

3. Printing label sticker function (Optional)

4. Bending shape frame. Use a circle wheel device to bend a circle frame or frame with circle corners. Min R60, Max R150, spacer sizes: 6A – 16A).

Product Details

Professional Customized Auto Insulating Glass Aluminum Spacer Strip Bar Bending Machine Could Foldable Special Shape Bending

Product Description

Jinan LIJIANG Glass Automatic Insulating Glass Spacer Bar Bending Machine is the special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication techniques. An automatic spacer bending machine can make a variety of convex polygonal aluminum frames by one aluminum strip at one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass better.

Advantages & Features

Benefits & Advantages

•Siemens 1200 PLC control system with fast working speed

•4 groups of storage (2 or 12 groups of storage can be optional)

•Automatically cut and feed aluminum spacers

•Automatically avoid the pins while bending and cutting

•Bend spacer frames continuously

•Aluminum spacers are available in sizes of 6A-27A

•Different bending tools for different sizes of spacers

•Pause and Reset the device for handling equipment failures

•Bend aluminum spacer, smooth stainless steel, warm spacer

•Connect to ERP system (Optional)

•USB input function, read the excel format file directly

•Automatically drill holes for filling argon gas (Optional)

•Spacer printing code function (Optional)

•Printing label sticker function (Optional)

•Bending shape frame. Use a circle wheel device to bend a circle frame or frame with circle corners. Min R60, Max R150, spacer sizes: 6A – 16A).

Different sizes of aluminum bars require different size tools(Optional)

The Unique ID Codes

All equipment spare parts have ID codes, which are matched with the ERP system of Lijiang Spare Parts Warehouse. When there is any after-sales problem, the defective spare parts can be found directly and replaced quickly.

The Printing Labels and Stickers

The spacer bending machine is equipped with the function of printing labels and stickers (optional), which can be easily removed, which is convenient for mass production of bending aluminum strips.

The Accurate Bending Effect

The corner error of the Aluminum Spacer Bar Bending Machine is less than 0.1mm, ensuring that it meets the practical application requirements of the hollow glass aluminum strip interval.

Specification

The Safety Components

In the heavy-duty connector part of the aluminum spacer bar bending machine, the electrical wiring is clearly an orderly market, and the installation and debugging are convenient and safe.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close