Vertical Insulating Air-floating Glass Processing Line

LJBZ2025GF

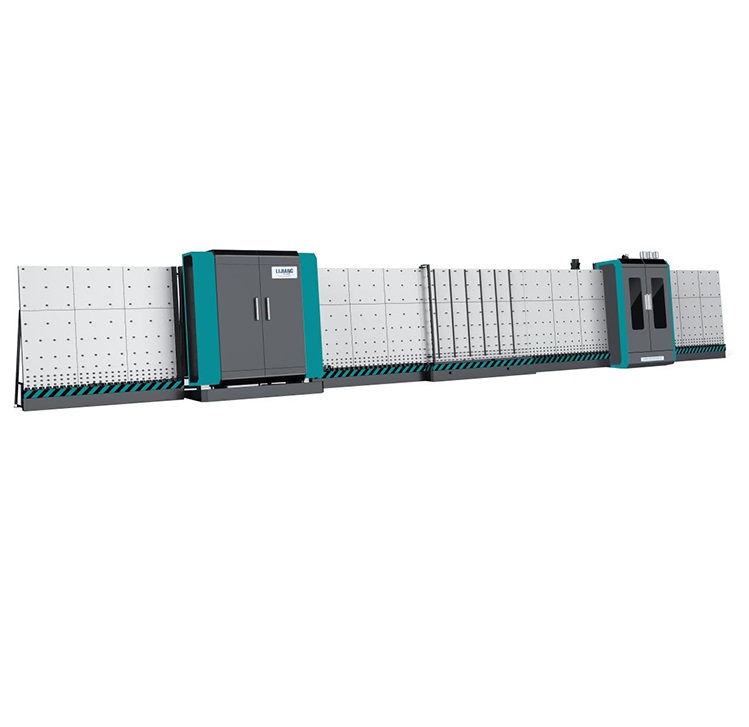

1. Air floating back plate , to avoid the wheel scraching the glass and leaving wheel marks

2. Two pieces of IGU could be pressed and filled gas in once time, high work efficiency

3. Gas filling in pressing,automatic filling the glass in different areas according to the size of glass

4. Germany Siemens PLC control system, touch screen interface

5. Automatic identification of coated and Low-E glass

6. 3 pairs of soft brushes can wash online and offline Low-E glass

Price

$9.99

Product Details

Vertical insulating glass production line is used for making insulating glass for homes, home windows and doorways, additionally for deliver, refrigerator, freezer and so forth. this ig line includes glass washing and glass pressing system, it is able to make double / triple glazing glass, for facets step glass. the elective function of filling argon gas is to be had, the air content is greater than ninety% as a minimum.

PERFORMANCE

Air floating back plate , to avoid the wheel scraching the glass and leaving wheel marks

Two pieces of IGU could be pressed and filled gas in once time, high work efficiency

Gas filling in pressing,automatic filling the glass in different areas according to the size of glass

Germany Siemens PLC control system, touch screen interface

Automatic identification of coated and Low-E glass

3 pairs of soft brushes can wash online and offline Low-E glass

The washing machine adopts SS material and waterproof device

Water tank with automatic temperature control and water washing system

Air heating system

Air Fan automatic start and stop setting

Noise reduction system

Online display of washing speed

Intelligent intermittent work, saving energy

Adjustable pressing board to keep the plate pressing surface straight

Automatic external rotary positioning system of glass

Connection mode of aviation plug

ERP system is optional

PARAMETER

Unit | LJBZ2025GF | LJBZ2535GF | LJBZ2535DGF | |

Power supply | 380V 50Hz 3P | |||

Total power | KW | 41 | 44.5 | 51.5 |

Washing speed | m/min | 2~10 | ||

Maximum working speed | m/min | 45 | ||

Minimum glass size | mm | 450*280 | ||

Maximum glass size | mm | 2000*2500 2000x3000 (Pressed by twice) | 2500*3200 2500*3500(Pressed by twice) 2500x4500(Pressed by twice, add suckers) | |

Flat glass thickness | mm | 3~15(3-30option) | ||

Washing brushes | Pieces | 6 | ||

Maximum thickness of insulating glass | mm | 60 | ||

Total gas consumption | L/min | 1200 | ||

Conveyer roll height | mm | 520 | ||

Dimension | L*W*H(mm) | 19500*3500*3200 | 23500*3500*3700 | 27000*3500*3700 |

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close