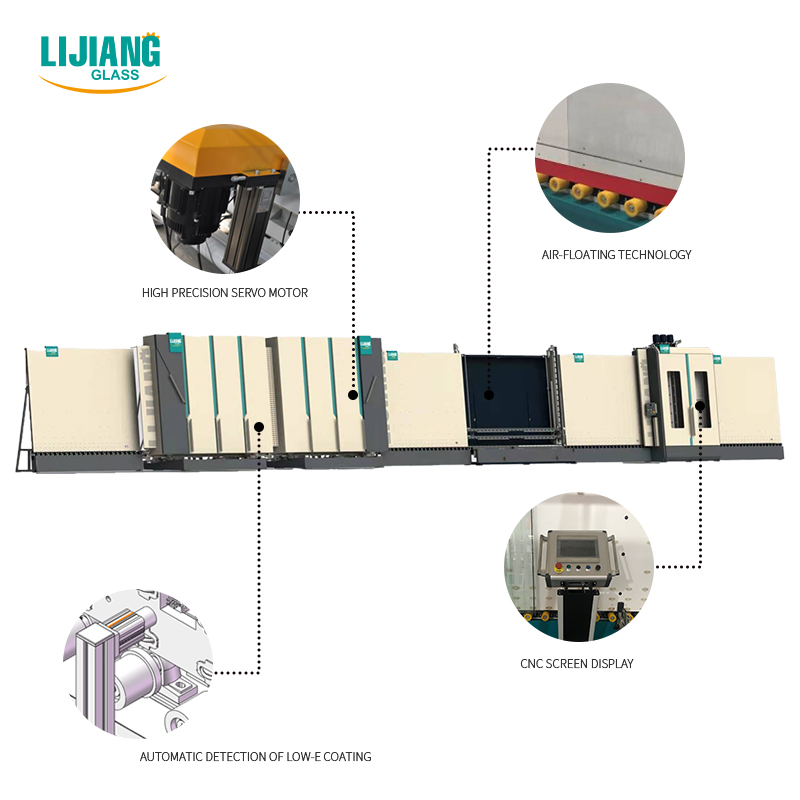

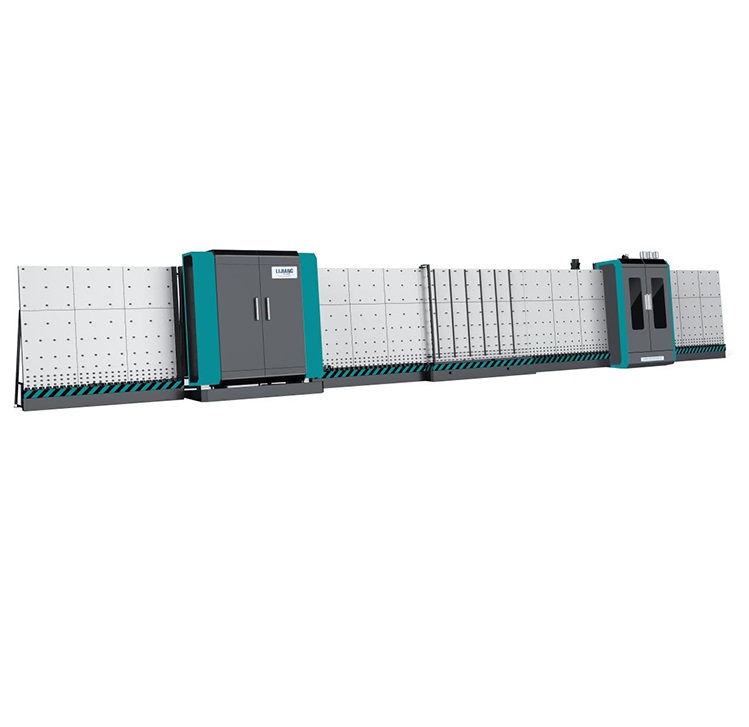

The whole insulating glass production line has 7 parts:

01 transmission segment;

02 Cleaning and drying section;

03 transmission segment;

04 Check the installation section.

05 transmission segment;

06 inflatable section;

07 Transmission segment.

Optional features:

• Step glass with optional edges

• Formed glass

• Automatic argon filling

• Air flotation technology transfer glass

•PLC control system, touch screen interface

• Siemens servo motor is used

• It is suitable for the production of double and triple layers of glass to prevent the glass from being contaminated by the wheel and leaving traces, improving the high quality of IG production.