Aluminium Spacer Bar Bending Machine for Insulating Glass Machine processing

switch input mode

Quick bending of aluminum strips

Various aluminum bar profiles can be bent

Automatic feeding system

A good after-sales service

Price

$30,000.00

Product Details

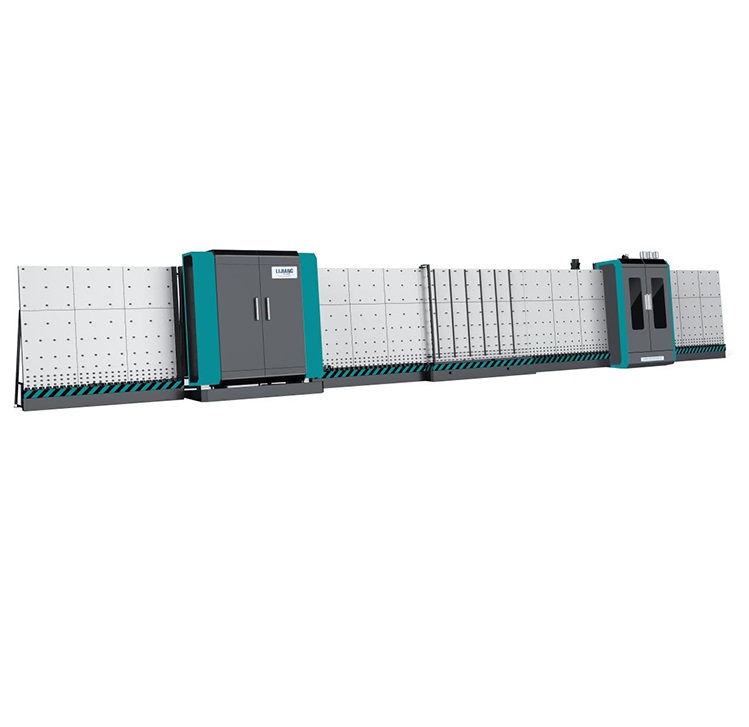

CNC automatic hollow glass aluminum spacer bending machine

Product description of automatic aluminum spacer bending machine

Automatic aluminum spacer bending machine LJZW2020

Jinan Lijiang Glass automatic hollow glass aluminum spacer bending machine is a special equipment for the production of hollow glass aluminum frame, replacing the traditional manufacturing process. Automatic interval bending machine can make a variety of convex polygonal aluminum frames with one aluminum strip at a time, so as to strengthen the strength of aluminum frames, so that the sealing effect of insulating glass is better.

The advantages and advantages of automatic aluminum spacer bending machine

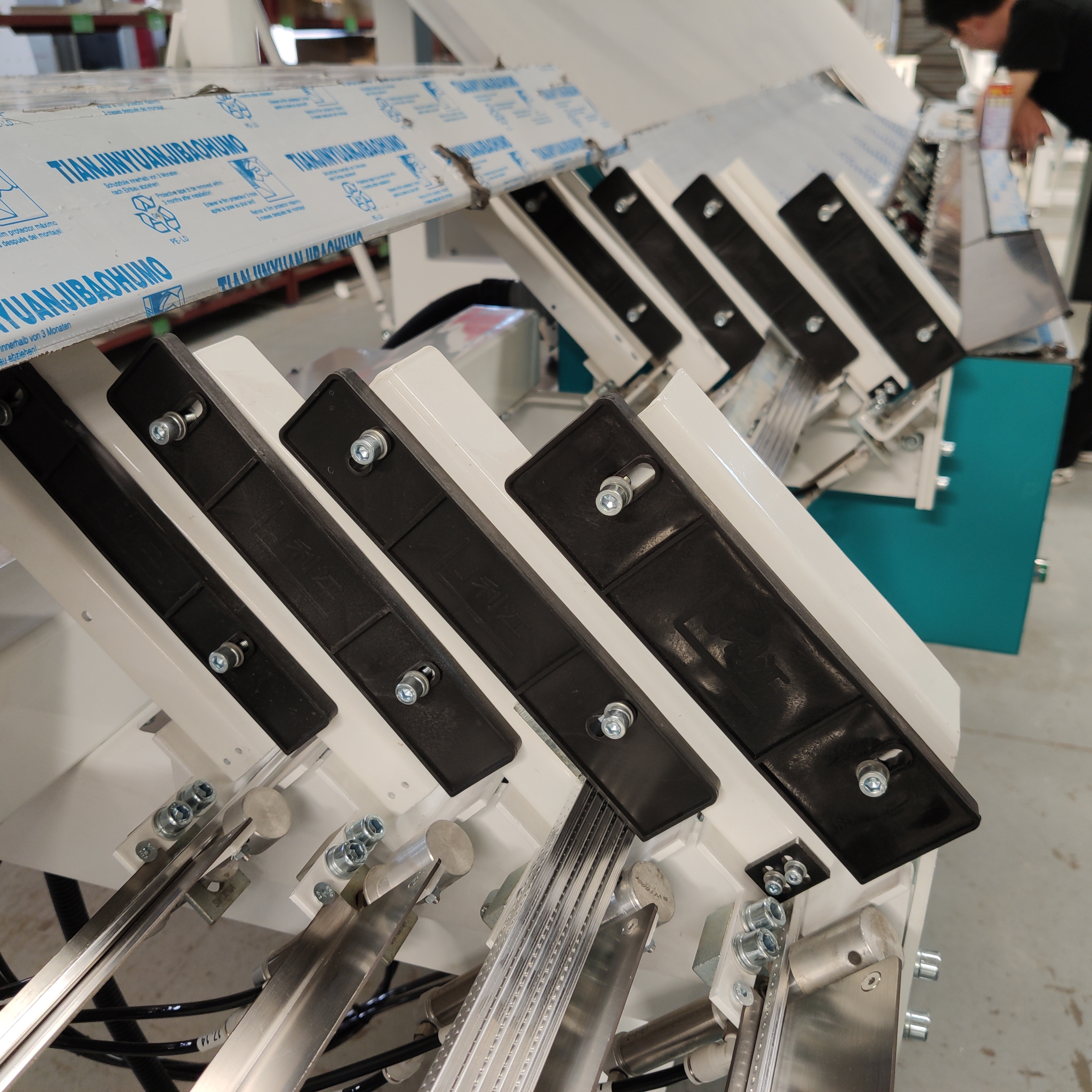

• Aluminum bar bending machine adopts Siemens 1200 PLC control system, fast working speed

• Automatic aluminum spacer bender has 4 groups of storage (optional 2 or 12 groups of storage)

• Automatic cutting and feeding of aluminium gaskets

• Automatic aluminum spacer bending machine can automatically avoid pins when bending and cutting

• Continuous bending spacer

Aluminum gaskets are 6A-27A in size

• Different bending tools are used for different sized gaskets of the aluminum strip bender

• Pause and reset the device to handle device failures

• Curved aluminum gasket, smooth stainless steel gasket, insulation gasket

• Connect to ERP system (optional)

•USB input function, directly read excel format files

• Optional function: automatic drilling and argon filling

• Interval print code function (optional)

• Printing label self-adhesive (optional)

• Curved shaped frames. Use a round wheel device to bend round frames or boxes with rounded corners. Minimum R60, maximum R150, interval size: 6A-16A).

• Optional assembly function: Different sizes of aluminum strips require different sizes of tools

Specification

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close