Insulating glass production and manufacturing line

1.Germany Siemens PLC control system, touch screen interface

2.Automatic identification of coated and Low-E glass

3.3 pairs of soft brushes can wash online and offline Low-E glass

Product Details

1. Usage

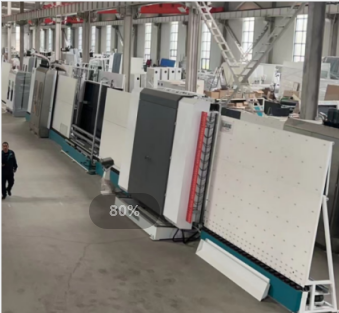

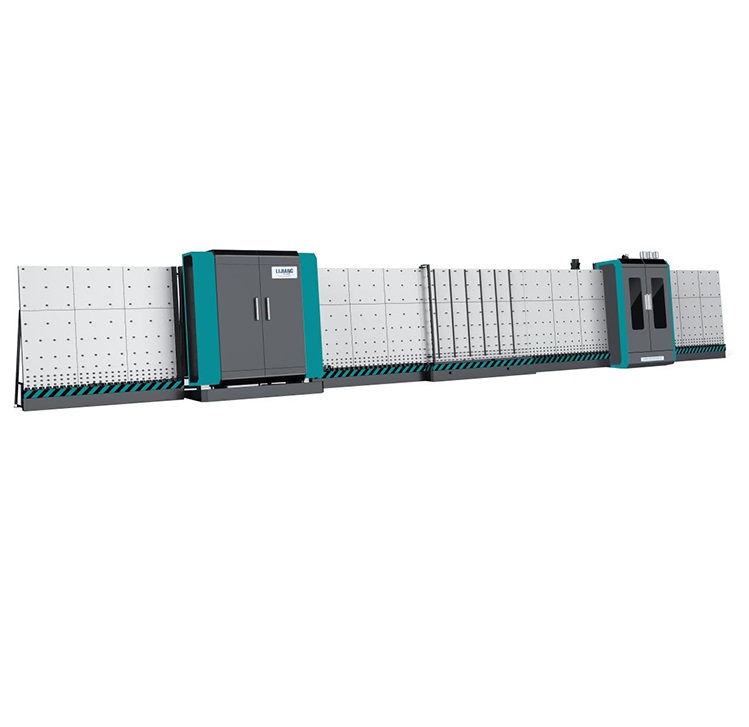

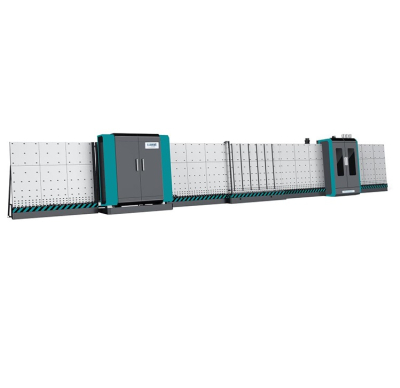

LJBZ2500PG Vertical insulating glass production line has the following functions: Washing glass, Installing aluminum frame, Pressing normal IG units, Pressing double IG units, Pressing double three-layers IG units.

LJBZ2500PG is a special equipment in the production of insulating glass with aluminum strip, which has so many advantages, such as small footprint, high efficiency, reliable performance, convenient maintenance and so on.

2.Main parameters

Power supply | Voltage | 380 |

Frequency | 60 | |

Total power | kW | ≈42 |

Washing speed | m/min | 2~10 |

Max.working speed | m/min | 45 |

Min.glass size | mm | 450×280 |

Max.glass size | mm | 2500×3200 2500×3500(Second pressing) |

Washing glass thickness | mm | 3~15 |

Max.insulating glass thickness | mm | 60 |

Conveyor height | mm | 500 |

Weight | kg | ≈8000 |

Dimension | L*W*H(mm) | 26850×3500×3700 |

3. Technology instruction

A、This machine adopts Siemens control system, equipped with high resolution touch screen, the operator can modify the working parameters of the production line at any time, and can clearly display the status of each input and output signal, which is convenient for the routine maintenance of the machine.

B、Machine is divided into manual and automatic control mode, each section can be controlled separately, easy to use, concise.

C、LJBZ2500PG Vertical insulating glass production line includes:

LJBZ2500PG Loading section

LJBZ2500PG Washing&drying section

LJBZ2500PG Convey section 1

LJBZ2500PG Convey section 2

LJBZ2500PG Inspection and frame installation section

LJBZ2500PG Flat press loading section

LJBZ2500PG Glass pressing and filling gas section

LJBZ2500PG Unloading section.

3.1 LJBZ2500PG Loading part:

3.1.1 Technical parameters:

Dimensions L,W, H | 3350×844×3000(mm) |

Power | 0.4kW |

Min.glass size | 450×280(mm) |

Max.glass size | 2500×3200(mm) |

Working speed | 2~10m/min |

3.1.2 Structural characteristics and functions:

The LJBZ2500PG Loading section is an inclined vertical structure. The transfer roller is wear-resistant, acid-proof and alkali-resistant polyamine roller, stepless frequency conversion speed regulation, glass can run smoothly at a suitable speed, the foot switch can start at any time according to the working conditions, stop the transmission. Coating detection alarm system can timely and accurately detect whether the coating surface of coated glass is placed correctly or not and the placement error, then the alarm of buzzer alarm, and the transmission stop at the same time

3.2 LJBZ2500PG Washing & drying section

3.2.1 Technical parameters:

Dimensions | 2420×1395×3700(mm) |

Power | 29kW |

Min.glass size | 450×280(mm) |

Max.glass size | 2500×3200(mm) |

Working speed | 2~10m/min |

3.2.2 Structural characteristics and functions::

LJBZ2500PG Washing & drying section is an inclined vertical structure. The control box is arranged outside the washing section for easy operation. The washing section and water tank are made of stainless steel and corrosion resistant material, the transfer roller is acid-alkali rubber roller, and the distance between the transfer rollers is automatically adjusted according to the thickness of glass.

The washing & drying section adopts stepless frequency conversion speed regulation, the glass can run smoothly at the right speed. The washing section has three pairs of brush with high pressure water sprayer to wash, can wash LOW-E glass; the drying section has a pair of inclined wind knife, according to the thickness of glass between the two air knife automatic adjustment, to ensure the air drying effect; the fan is 15KW fan.

The water system consists of two independent waterway circulation systems: the primary washing system and the secondary rinsing system. The glass is first washed through the water route and then rinsed by the water route. The water is pumped from the water tank and sprayed onto the glass surface through a spray pipe. After washing the glass through the brush, it flows back to the water tank for recycling. The primary washing water tank with temperature control water heating device, can automatically maintain the water temperature.

In order to ensure the washing effect, the electrical conductivity of the cleaning water should not be greater than 40µs. If the water quality is poor, the water treatment device should be equipped. After the water treatment, the water enters the rinsing water tank, and the water treatment device shall be used for recycling according to the above steps. The water treatment should be prepared by user.

3.3 LJBZ2500PG Convey section 1,Convey section 2:

3.3.1 Technical parameters:

Dimensions | 3350×844×3000(mm) |

Power | 1.5kW |

Min.glass size | 450×280(mm) |

Max.glass size | 2500×3200(mm) |

Working speed(double speed) | 2~45m/min |

3.3.2 Structural characteristics and functions::

The Convey section 1and Convey section 2 are inclined vertical structures. The transfer roller is wear-resistant, acid-resistant and alkali-resistant polyamine roller, stepless frequency conversion speed regulation, glass can run at a suitable speed and stable. Two transfer motors capable of storing two pieces of glass with less than 1.5 meters in length at the same time

3.4 LJBZ2500PG Inspection and frame installation section

3.4.1 Technical parameters:

Dimensions | 3800×1121×3100(mm) |

Power | 1.9kW |

Min.glass size | 450×280(mm) |

Max.glass size | 2500×3200(mm) |

Working speed(double speed) | 2~10m/min 2~45m/min |

3.4.2 Structural characteristics and functions::

LJBZ2500PG Inspection and frame installation section is inclined vertical structure. The transfer roller is wear-resistant, acid-resistant and alkali-resistant polyamine roll. The transmission is frequency conversion speed regulation, the running speed is stable. The aluminum frame positioning device and the glass positioning device are divided into two sets, the two pieces of glass with length less than 1.5 meters can be positioned simultaneously. The depth of two-component polysulfide glue can be adjusted by the digital display on the handwheel shaft and the orientation of the glass side and the aluminum frame. High quality inspection lamps, can clearly check the quality of washed glass.

3.5 LJBZ2500PG Flat press loading section:

3.5.1 Technical parameters:

Dimensions | 3350×844×3000(mm) |

Power | 0.75kW |

Min.glass size | 450×280(mm) |

Max.glass size | 2500×3200(mm) |

Working speed | 2~45m/min |

3.5.2 Structural characteristics and functions::

The LJBZ2500PG flat press loading section is an inclined vertical structure. The transfer roller is wear-resistant, acid-proof and alkali-resistant polyamine roller, the double transmission motor adopts stepless frequency conversion speed regulation, the glass can run smoothly at a suitable speed. This section is used as the storage area of the small glass and the storage of the super-long glass. It can store two pieces of glass with length less than 1.5 meters at the same time, which improves the production efficiency of small glass. Equipped with glass and aluminum frame automatic detection mechanism for the pressing and filling gas section to provide inflation parameters.

3.6 LJBZ2500PG Glass pressing and filling gas section:

3.6.1 Technical parameters:

Dimensions | 3700×2185×3230(mm) |

Power | 4.7kW |

Min.glass size | 450×280(mm) |

Max.glass size | 2500×3200(mm) |

Working speed | 2~45m/min |

3.6.2 Structural characteristics and functions::

LJBZ2500PG Glass pressing and filling gas section is suitable for pressing double IG units or three-layer IG units at the same time. All kinds of flat glass (including coated glass and glass-clamped glass) can be pressed by this machine.

LJBZ2500PG is a pressing machine with a new filling gas technology. This equipment is suitable for high and new technology glass pressing and filling gas machine with various gases or mixed gases. Because the control system detects preset types of gases (including mixing ratio of mixed gases) and flow rate before each gas or mixture is filled with insulating glass.

LJBZ2500PG is not suitable for bow glass or twisted glass because the plane inside the pressing section is immutable.

LJBZ2500PG can be used to measure the gas concentration of insulating glass on line. The measuring device in front of the equipment can accurately measure the size and thickness of the glass and calculate the amount of gas needed.

LJBZ2500PG can press and fill gas into two pieces of IG units whose length is less than 1.5m at the same time, which greatly improve the production efficiency, especially for the glass whose length is less than 1.5m.

3.7 LJBZ2500PG Unloading section:

3.7.1 Technical parameters:

Dimensions | 3350×844×3000(mm) |

Power | 0.75kW |

Min.glass size | 450×280(mm) |

Max.glass size | 2500×3200(mm) |

Working speed | 2~45m/min |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close