Automatic Insulating Glass Production Line

1). Making double IG units

2). Making triple (3-layer) IG units

3). Making low-e IG units

4). Making four-sides IG units

5). Making shaped IG units

6). Filling argon gas automatically

Price

$9.99

Product Details

APPLICATION

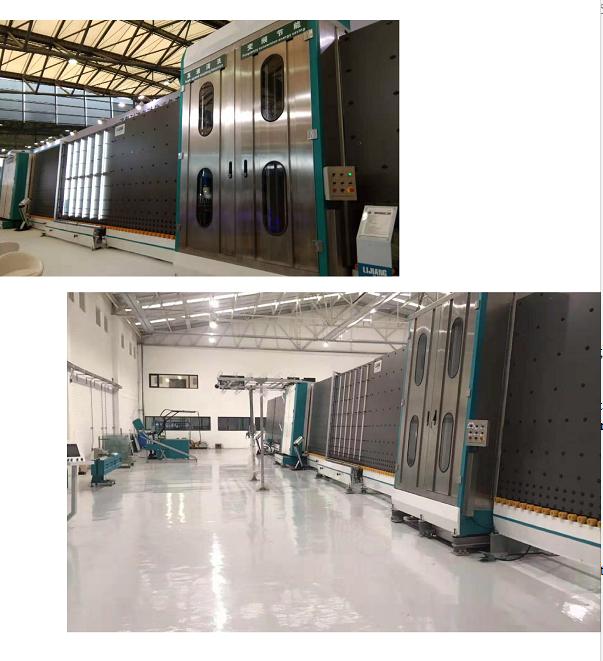

Lijiang Production Line adopts the latest production technology, its main purpose is to create high-end quality, provide customers with the latest production technology and a complete set of product solutions, improve production efficiency, save production costs, and generate maximum benefits.

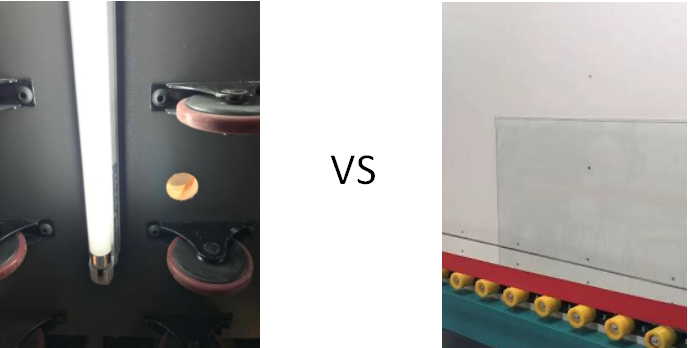

At present, Lijiang hollow glass production line mainly adopts the new technology of air flotation to transport glass. This new technology is to prevent glass from being contaminated by wheels and leaving marks, so as to improve the quality of IG production.

Detailed description

1. Air flotation technology

Air flotation technology is a new technology that uses air to support and transfer glass. When the glass is cleaned from the cleaning section of the production line, it is transported by air so that it does not contaminate the glass. To ensure that the insulating glass produced is of the highest quality.

2.There are Low-e glass sensors in the cleaning section of the insulating glass production line

The Low-e glass sensor is installed before the cleaning section. It can automatically identify Low-e glass surface quickly and accurately to prevent glass from falling off the Low-e surface.

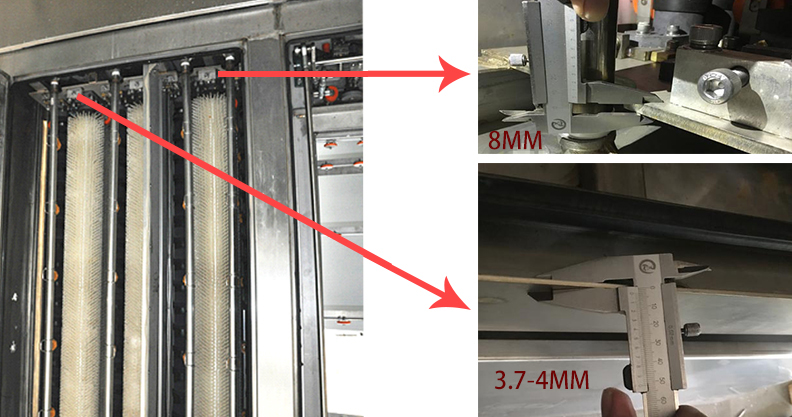

3. The cleaning section is made of 304 stainless steel

The whole cleaning and drying section is made of 304 stainless steel material, including the plate and internal spare parts.

The thickness plate can up to 4mm and the interior plate can be 8mm.The equipment performance is better and service life is much longer.

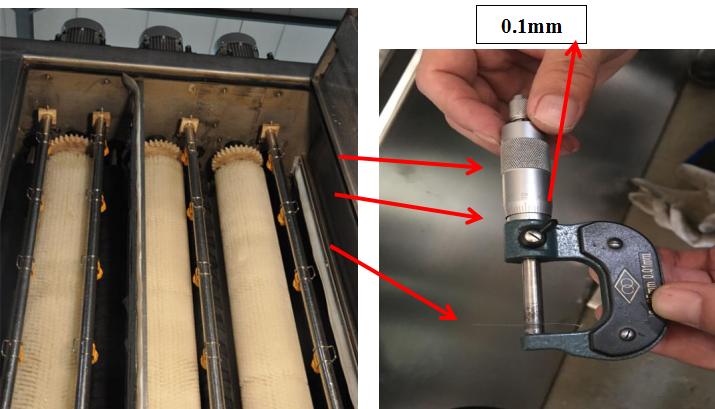

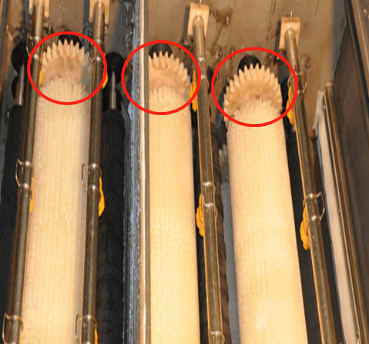

4. Use 6 soft (Low-e) brushes, only 1mm in diameter, for the cleaning and drying section.

6 soft (Low-e) brushes for cleaning low-e glass, plate glass, tempered glass, etc. With a diameter of less than 0.1mm bristles, never damage the glass, especially suitable for low radiation glass.

5. European advanced anti-noise system is adopted in the cleaning and drying section to create a good working environment for employees

The noise can be kept below 90 decibels using nylon gears and sponges.

6. Water heating system and water filtration system

Due to the different water quality in different countries, in order to ensure that the glass is washed clean enough, air heating system is used to clean the glass with soft water. What's more, water filtration system is adopted to make water circulation, save water and keep water clear. Play a double filling role.

7. The special structure inside the cleaning and drying section of the production line can automatically identify the thickness of the glass. Allow rapid transfer of glass of different thicknesses to increase production speed. After testing, it only takes 22 seconds to produce 1 meter * meter insulating glass.

1). There is a universal joint device to avoid damage to the glass due to changes in the thickness of the glass. When the thickness of the glass changes, the wind knife will move back and forth to adjust the distance, so that the relative distance between the wind knife and the glass is constant.

2). The glass bottom on both sides of the sprocket active transfer glass, can maintain a fast transfer speed, not only to ensure the large size of the glass fast transfer, small size of the glass can also be fast transfer.

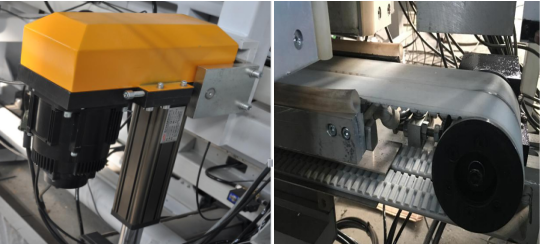

8. The plate pressing section adopts servo motor and synchronous belt support to press IG unit.

The servo motor can accurately calculate the thickness between the glass and the aluminum. Can ensure accurate working pressure, prevent glass damage, while improving the working speed.

In addition, the synchro belt is zigzag, making the pressing more accurate.

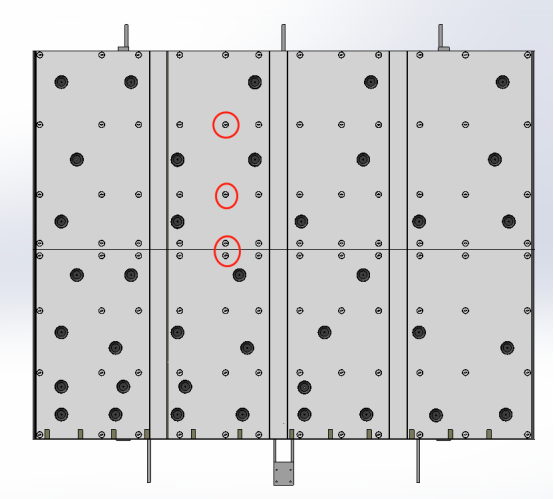

9. China's first use of adjustable point plate pressing technology, to ensure that the pressure plate never deformation.

Plate press adopts numerical control technology. We designed adjustable points inside the platen to keep the platen back straight at all times. It can always be vertical and straight.

10. Plate pressure section energy saving

Three microswitches are used in the plate press section to divide the pressed part into four areas.

When each microswitch receives a signal, it adds a portion of the working area. When the corresponding micro switch is not touched, the area does not work. This makes the machine very energy efficient

When glass L≤1.5m, zone 1 works.

Zones 1 and 2 work when glass L =1.5m-2.3m.

Zones 1, 2, and 3 work when the glass is 2.3m < L < 3.2m.

When the glass is 3.2m = L≤4m, the regions work together.

Moreover, the sides and bottom of the press box are sealed to ensure the inflation effect. It can save a lot of argon gas and electricity.

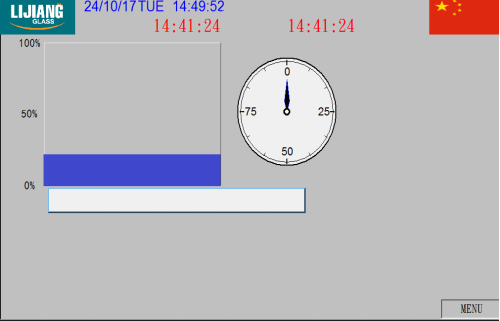

11. Automatic high-speed argon filling

It only takes 22s for a 1m*1m double glass to be filled with argon. The argon gas value can be set and displayed directly on the screen. Argon content and filling speed can be visually observed on the screen.

When the two pieces of glass are closed, it fills with argon gas from the bottom of the glass. When the previous set point is reached, the inflation will stop automatically.

12. Main functions

1). Making double IG units

2). Making triple (3-layer) IG units

3). Making low-e IG units

4). Making four-sides IG units

5). Making shaped IG units

6). Filling argon gas automatically

Technical data

Max. glass size | 2500mm*3500mm |

Min. glass size | 280mm*450mm |

Glass thickness | 3-15mm |

Insulating glass thickness | 60mm |

Glass washing speed | 2-10m/min |

Glass conveyor speed | 45m/min |

Washing brushes | 3 pairs |

Water supply | Water consumption:0.5t/h conductivity:40μs/cm |

Air supply | Flow: 0.8m/min |

Air pressure | ≥0.8MPa |

Total power | 3P 380V 50HZ 44.5KW |

Dimension | 23500*3500*3700mm |

Weight | 6500kg |

Electrical parameters

NAME | ORIGIN | BRAND |

Transfer motor | Germany | SIEMENS |

Brush motor | Germany | SIEMENS |

Servo motor | Germany | SIEMENS |

PLC | Germany | SIEMENS |

Low voltage electrical appliance | Germany | SIEMENS |

Frequency converter | Germany | SIEMENS |

Micro Switch | Taiwan | TEND |

Button and indicator light | France | SCHNEIDER |

touch screen | Taiwan | WEINVIEW |

Intermediate relay | Japan | OMRON |

Water pump | China | LINGXIAO |

Guide | Taiwan | HIWIN |

Pneumatic Components | Taiwan | AIRTAC |

electric gauge | China | MIRAN |

Photoelectric switch | Korea | AUTONICS |

JINAN LIJIANG AUTOMATION EQUIPMENT CO.,LTD | ||

Send your message to us

Submitted successfully

We will contact you as soon as possible

Close