Automatic Spacer Bending Machine LJZW2020

1. Adopt the servo control feeding system, spacer frame size can be adjusted with an accuracy of 0.1 mm/m

2. CNC bending angle control system with adjustable accuracy of 0.1°

3. Set up four groups of spacers storage units

4. Aluminum bar with multiple sizes can be selected at will

5. Automatically adjust the bending speed according to the size of the aluminum frame to avoid the deformation of the large frame and ensure the high speed and continuity of the small frame

Price

$9.99

Product Details

Application

Automatic spacer bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology. This equipment can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better.

Equipment details

Adopt Siemens PLC control system

There are 4 Siemens servo

Adopt 12 sets of racks which could storage more different sizes of spacers. Use Siemens servo to change different racks.

Automatically cut and feed aluminum spacers

Bend shaped spacer frames continuously

Automatically avoid the connecting corner while bending and cutting

The machine grabs the spacer from the top instead of grabbing the spacer from bottom, solving the old-fashioned reversing problem.

Using industrial computer technology which could realize the on-site drawing by workers on the industrial computer and directly bending the drawn graphics.

The special machine hand device is used to bend big spacer frame | Heavy duty connectors is convenience and safety for installation and debugging |

|  |

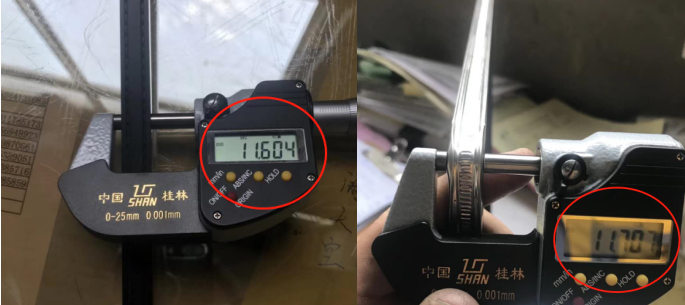

| Spare parts of all machine have ID codes. | Precise bending effect, corner error less than 0.1mm. |

|  |

Leading Technology

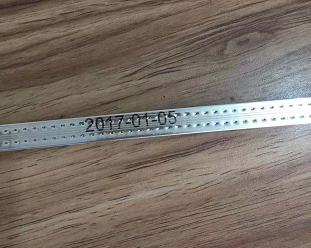

| Spacer printing code function (Optional) | Automatic drill gas filling hole (Optional) |

|  |

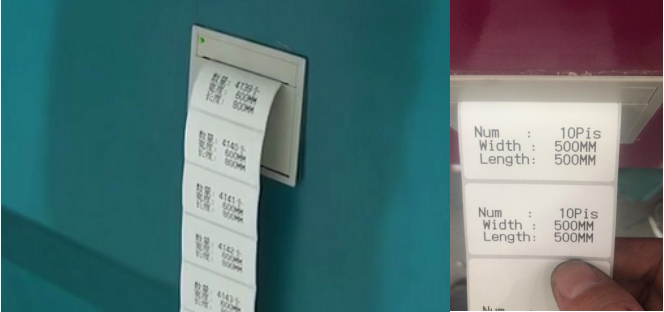

Printing paper label sticker function (Optional),could remove it easily.

USB input function, read the excel format file directly etc (Optional)

Connect to ERP system (Optional)

Can bend aluminum spacer ,Technoform, Alupro, Thermix, warm spacer (Swisspacer) and stainless steel ( Optional) and so on.

We have the special soft system which could avoid the 120mm to reduce waste. For example, if the length of the gusset is 60mm, when the program calculates the right angle, there is a gusset. When you start to bend the rectangular frame, you need firstly transport 120mm, then cut 120mm, and then step on the pedal to bend frame, so you will waste the 120mm.

Technical data

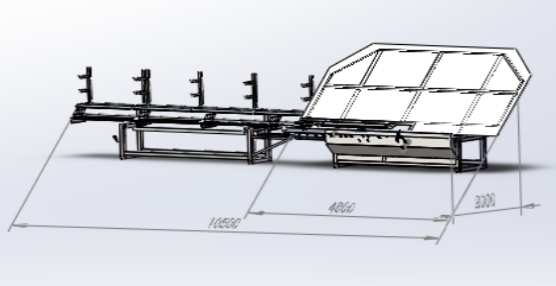

Max.bending size | 1800mm*2000mm (2500mm*4000mm) |

Min.bending size | 150mm*300mm |

Aluminum spacer width | 5.5-26.5mm |

Dimensional error | ±0.5mm |

Angle error | ±1º |

Processing speed | ≤26s |

Air supply | ≥0.65MPa |

Total power | AC220/380V 50Hz 2.5KW |

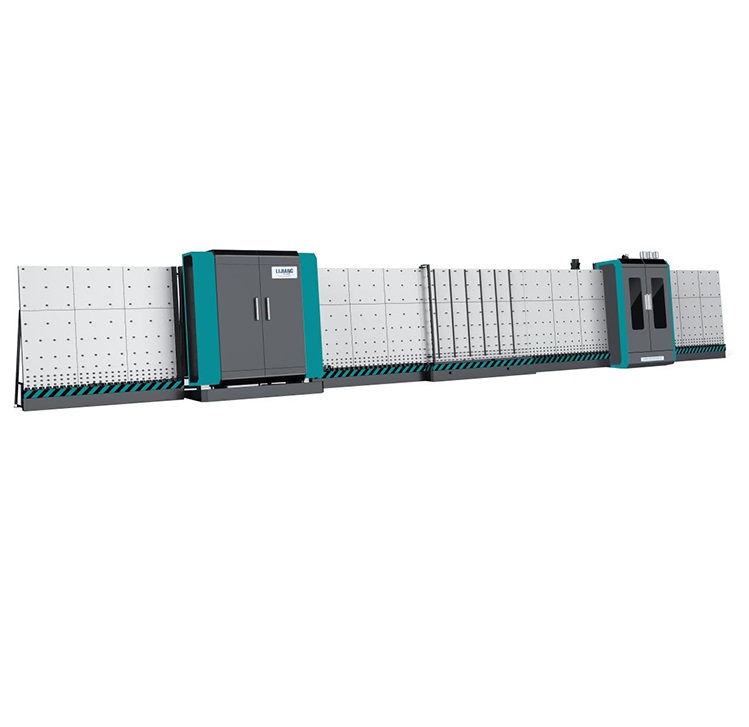

Dimension | 10500mm*2200mm*2600mm |

Electrical parameters

NAME | BRAND | NAME | BRAND |

PLC | GERMAN SIEMENS | Triplet | Taiwan AIRTAC |

Low voltage electrical apparatus | GERMAN SIEMENS | Cylinder | Taiwan AIRTAC |

Servo motor | GERMAN SIEMENS | Solenoid valve | Taiwan AIRTAC |

Servo driver | GERMAN SIEMENS | Switch power | Taiwan TEND |

Relay | JAPAN OMRON | TOUCH SCREEN | Taiwan WEINVIEW |

Sensor | KOREA AUTONICS | GUIDE | Taiwan TBI |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close