Tempered Glass Heat Soak Furnace

The Main Technical Performance:

The Heating Soak Test Furnace was designed and manufactured according to European safety performance test standard of toughened glass, energization and electricity stoppage of heater adopt solid state relay; technological parameter and program control use computer memory saving and intelligent control, temperature adjustment mode is automatically accomplished by PLC control system; automatic storage of temperature curve and print test report of every time; there are altogether 3 sets blowers to form forced convection circulation system of hot wind, in addition, fitted with 1 inverter blower used for automatic control of cooling rate of unit which is used for control the cooling system constantly reduce temperature; There are 6 thermocouples on top of the furnace body to monitor the temperature in the furnace. And 20pcs thermocouples used for supervising temperature status of glass surface, 32pcs thermocouples on the computer operation interface display information at right time.

Product Details

Here is the tempered glass homogeneous furnace’s actual parameter and the configuration. If you have further question, please call us anytime.

1. The Main Technical Standard:

1.1 Device Structure: The Furnace one side door is able to open, 1 set of loading machine with wheel for 3.66 meters long glass loading.

1.2 Device Specification:

Device outside dimensions:L4300×W2200×H3300 mm

Device inside dimensions:L3995×W1200×H2650mm

Covers an area of:L10000×W4000×H4300mm

1.3 The Glass Production Specification:

Homogenous Glass The hugest size: 3660×2100 mm

Glass Thickness Range: 4-19mm

1.4 Product Performance: EN14179-1:2005

1.5 Total Power:164.5KW(Heating power 144KW)

1.6 Voltage: 3 Cabins 380V /60Hz

Technology parameters

1.Device outside dimensions: L4300×W2200×H3300 mm

2.Device inside dimensions: L3995×W1200×H2650mm

3.The maxi size of glass :3660*2100mm

4.Thickness of glass: 4-19mm

5.The highest temperature: 340℃

6.Working temperature: 290℃±10℃

7.Total power: 164.5KW

8.Heating power:144KW

9.3 sets of forced convection fans on the top( 5.5 kw/set)

10. 1 set of cooling fan( 4 kw/set), use cool water cooling system and air cooling cooling system.

11. 6 pcs of cold wind door, open and colse by air cylinder.

12.one side open of the furnace .

13. 1 set of 3.66 meters long A sheet, the bottom plate is weld for broken glass.

14. Source: 0.5-0.7 MPA

15. Weight: 7T

16. Production capacity:5000 KG/Circle

Process parameters:

According to EN14179-1:2005 standards, it can achieve the following temperature and wind cycling by computer logic control

●Normal heating temperature(Below 50℃) to limit requirements temperature (290℃±10℃) 60 min-120 min;

●Keep the top limit temperature (290℃±10℃) 120 min-480 min;;

●Temperature to cooling temperature (70℃)120min--480min;Themaximum temperature is able to adjust

●±10℃ Empty furnace :the biggest difference temperature: ±10℃

●±10℃ Full furnace temperature: the biggest temperature difference is :±10℃;

●Constant temperature: normal temperature to 320 degree, can be set in a random;

●Constant temperature and time limit alarm temperature can be set in a random;

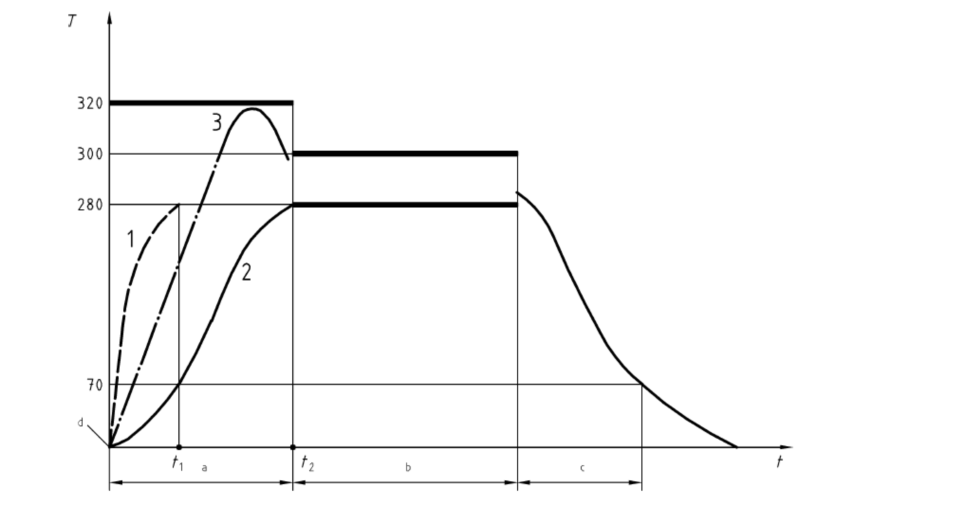

Heat soak time/temperature rules

To implementation of the equipment acceptance work to achieve EN14179-1:2005.The following requirements for process and control, as below:

1, calibration standard:

Homogeneous system must follow the picture 1. The system must be able to achieve the load of 100% and 10%.

Picture 1 Standard Homogeneous time/Temperature rules

T Any pints of glass temperature.

t Time hour

t1 Time of first piece of glass to 280℃

t2 Time of last piece of glass to 280℃

1 The first piece of glass temperature to 280℃

2 The last piece of glass temperature to 280℃

3 Glass temperature

a Heating period

b Constant temperature period

c Cooling period

d Ambient temperature

Note 1: full load depends on the size , the thickness of the glass and furnace volume. General base on 6 mm or 8 mm thickness, the distance between the glass depends on the location, type of glass and interal things shape decision.

Note 2: The minimum distance is 20 mm.

2. the collection of temperature

Inner furnace is no less than 6 points fixed temperature gathering and glass surface is more than 20 point temperature gathering, this some points is under the standards of the EN14179-1:2005 of installation, put, calibration .

Note 1: the furnace and glass surface temperature can be tested in full load .

Note 2: the furnace temperature can control unit monitoring at the air outlet. Glass surface temperature is measured of the hot good contact thermocouple in the glass surface.

Single Convection

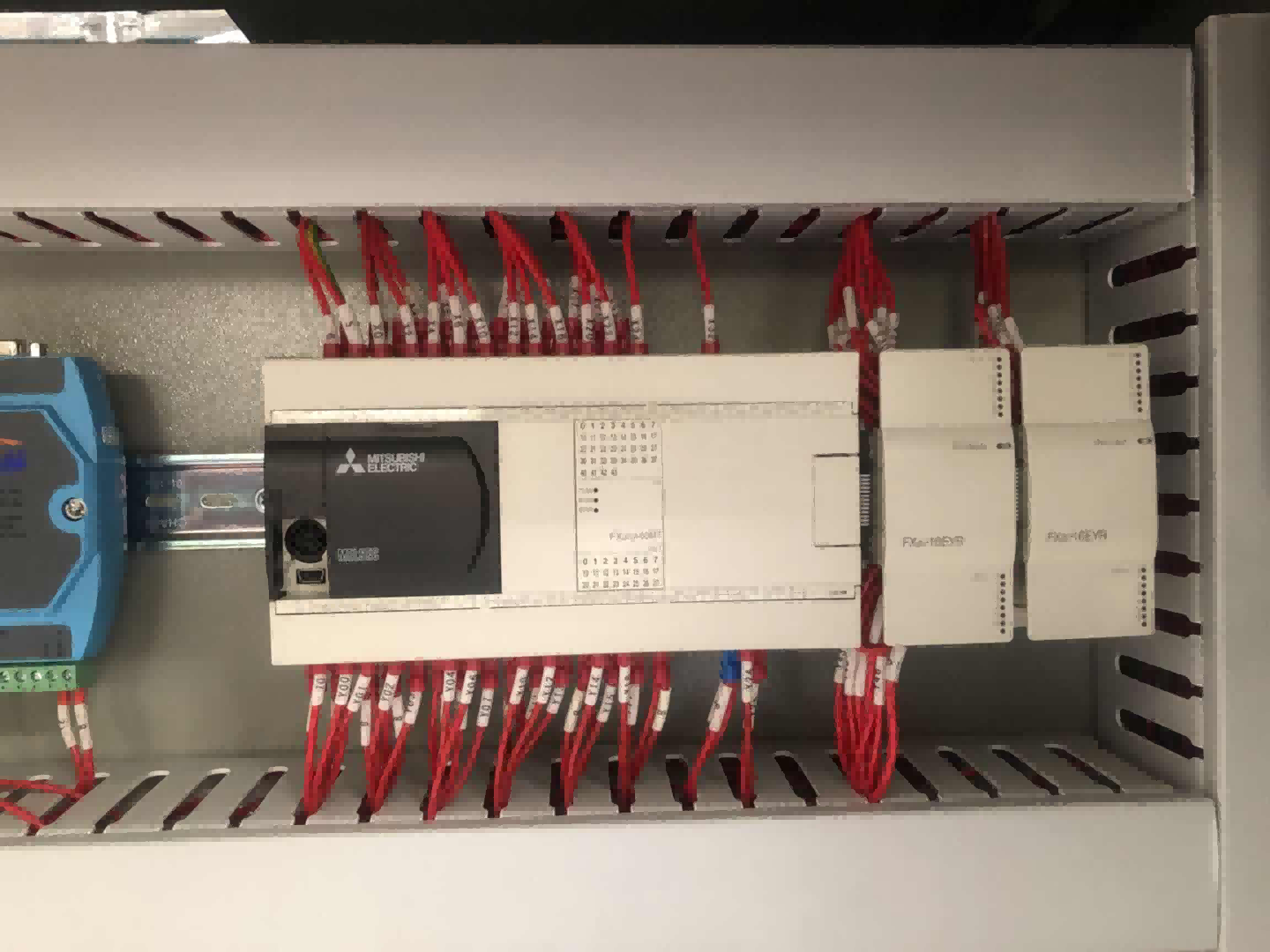

Mitsubishi PLC

circuit breaker

PLC protection switch

Heating protection system

Ammeter

Glass homogenizer (hot-dip) furnace LJJZ2100/3660main configuration list | |||

Name | Specification | Qty | Brand |

Furnace Steel pipe | 60*80 | Chinese Standard | |

Furnace door’s pipe | 50*100 | Chinese Standard | |

Steel pipes of the glass loading trolley | 80*80 40*40 | Chinese Standard | |

Furnace Cold Plate | Chinese Standard | ||

Furnace Hot Plate | Chinese Standard | ||

Furnace Interior | Stainless steel plate | Chinese Standard | |

Furnace duct interiors | Galvanized sheet | Chinese Standard | |

Punching guard outside the furnace | Cold Plate | Chinese Standard | |

Glass loading trolley rolling axis | 60mm diameter round | Chinese Standard | |

Convection Blower | 5.5Kw | 3 sets | CHINA |

Cooling Fan | 4Kw | 1 set | CHINA |

PLC | 1 pc | MITSUBISHI | |

PLC Expand | 1 pc | MITSUBISHI | |

Frequency Converter | 1 pc | MITSUBISHI | |

Solid-State Relay | 18 pcs | GOLD | |

Fuse | 18 pcs | MRO | |

Computer | 1 pc | Advantech | |

monitor | 1 pc | DELL | |

Electric Appliance | Schneider+Delixi | ||

Temperature acquisition module | 4 pcs | Beijing | |

Temperature control software | 1 set | Beijing kingview | |

Control Software | CHINA | ||

Heating Tube | 36pcs | CHINA | |

Solenoid Valve | AirTAC | ||

Track | 1210 # rail steel | CHINA | |

Glass Spacer | Isolated glass width 10mm | 100pcs | CHINA |

Pack list

Serial number | Generation number | Product name | Quantity | Remark |

1 | 工具箱/ toolbox | 1 | ||

2 | 8X10,12X14,17X19,22X24 | 开口扳手/ Open-end wrench | 各1/Each 1 | |

3 | S=6,8,10 | 内六角扳手/ Open-end wrench | 各1/Each 1 | M8,M10,M12 |

4 | 17×19,22×24 | 梅花扳手/ Plum blossom wrench | 各1/Each 1 | |

5 | 活动扳手 / Monkey wrench 12″ | 1 | ||

6 | 十字螺丝刀/ Socket wrench | 1 | ||

7 | 一字螺丝刀/ Cross- screwdriver | 1 | ||

8 | 剪刀 | 1 | ||

10 | 卡簧钳(轴卡)/ Card spring clamps (axis card) | 1 | ||

11 | 电磁阀/ Electromagnetic valve | 2 | ||

12 | T型套筒板手M8 | 1 | ||

13 | 5mm高温钢丝布/ Heat wire cloth | 5m | ||

14 | 装箱单/Packing list | 1份 | ||

15 | 热电偶/Thermocouple | 6个 | 配2个 | |

16 | 高温线/High-temperature line | 5m | ||

17 | 固态继电器/Circuit breaker | 2 | ||

18 | 交流接触器/Ac contactor | 2 | ||

19 | 熔断器/fuse | 2 | 茗蓉 | |

20 | 金属屏蔽热电偶线 /The metal screen thermocouple wire(补偿导线/compensation conductor) | 5卷/roll | 配1卷 | |

21 | 发热管/heating tube | 2条 | ||

22 | 玻璃间隔块/Glass interval tube | 100套/ pcs |

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close