Glass Lifting Machine

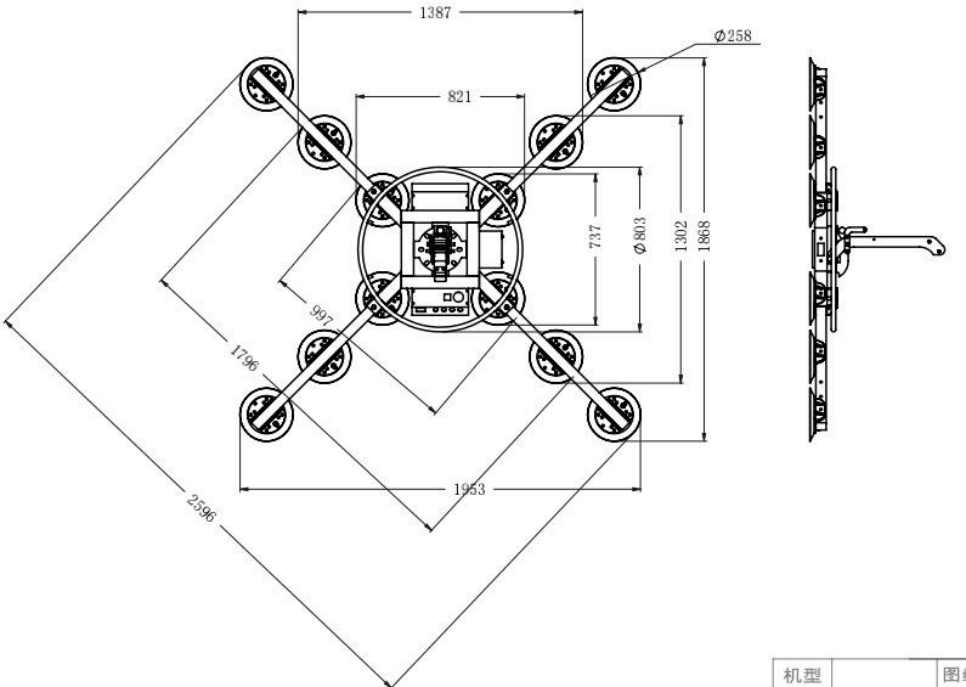

1. (Six of Silica gel, #60 filter screen 10’’[30m] diameter.

2. Manual 90°, with for-bar tilt linkage that minimizes operator effort and automatically holds a correctly attached load in the upright or flat position. When engaged, tilt locks ensure that the orientation of the load is not compromised by accidental or unexpected forces.

3. Manual 360°with automatic latching(when desired)

4. Diaphragm type, 1 SCFM[28liters/minute] nominal airlow

Product Details

Designed for used with a crane or other hoisting equipment, the RSY-600-6 lifters employ vacuum to hold a load for lifting, and they provide manual 360°rotation and mechanically assisted, manual 90°tilt movements for load manipulation.

Length | Maximum | 2596mm | |

Minimum | 997mm | ||

Width | Maximum | 1868mm | |

Minimum | 821mm | ||

Per-Pad | 184lbs[100KG] | ||

Maximum | [800Kg] | ||

[140KG ] | |||

12Volts DC, 10Amps | |||

7 amp-hours | |||

Step 1: Use the glass lifter sucker slowly close to the glass, and then the main power switch (⑦) ON, the vacuum pump switch (⑧) ON. When vacuum Gogel (⑥)= -65(negative pressure motherboard =-65), glass lifter sucker can be used to lift glass.

Step 2: Lift the glass to the desired position with the glass lifter sucker, then set the glass release switch (⑨) in the ON position.

Simple and convenient operation

Example Change Pad enclosure configurations

Glass lifts are offered in a variety of cushion frame configurations with different load sizes and weights. A configuration can be selected to provide optimal load surface support and minimize load overhang

Note: When the vacuum pump is working and the negative pressure is < -65, the glass can be lifted by the glass lifter sucker. Check all suckers and glass for water, oil, stains, etc. When the pump is working continuously, check whether there is water, oil, or stains between all the suckers and the glass, and check whether the glass release switch is OFF.

Send your message to us

Related News

Submitted successfully

We will contact you as soon as possible

Close